Testimoniazas

> Testimonial TECHBELT> Testimonial TESA UK

> Testimonial MASK-OFF

> Testimonial GARLOCK

> Testimonial ENGLEWOOD

> Testimonial AMERITAPE

> Testimonial NFK

> Testimonianza W.E.T.

> Testimonianza FIXUS TRADE

> Testimonianza Klinbeil

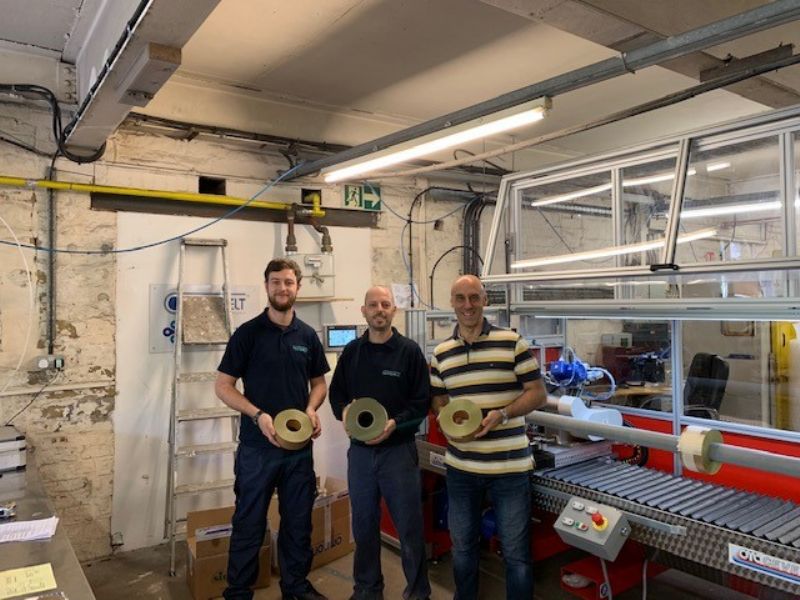

Techbelt invest in CEVENINI cutting edge technology will benefit its customers

Techbelt UK operation, based in Halifax, has purchased a state-of-the-art slitting machine that will ensure the company meets the demand for bespoke PTFE coated tapes for many years to come.

With the existing manual machine running at full capacity in 2019, the company’s decision to purchase a new automated CEVENINI machine was easy to make. Simon Sparkles was given the responsibility for sourcing the replacement and after evaluating machines from other manufacturers a decision was made to buy a Cevenini machine.

Once the order for the Cevenini E305 was placed, a broad range of materials were sent over to Cevenini’s manufacturing operation in Concorezzo, Nr Monza, Italy for slitting evaluation and proving on the new equipment. The optimum slitting parameters were reached for each product and programmed in memory. This enabled the commissioning of the new machine to go smoothly and limit the ‘learning curve’ for the new operators.

The key to and aims of the new investment are:

· Improve slitting quality of the tape products.

· Reduce production cycle times for better efficiency

· Shorten lead-times for our clients

· Slit rolls to higher accuracy

· Reduce waste

The new machine ticks all the boxes and more besides.

The new technology in the Cevenini E305 brings greater efficiencies and greater flexibility and a higher degree of accuracy to the range of our log slit tapes. The advantages compared to the old machine are huge and the automation allows our operatives to better utilize their time whilst the machine is working. These efficiencies translate to giving TECHBELT a competitive ‘edge’ and its customers a more extensive selection of bespoke products to suit their requirements to a finer tolerance of +/-0.1mm.